Products series

Specializing in precision parts

Feedthroughs for Airbags and Seatbelts

Feedthroughs for Airbags and Seatbelts for airbag gas generator and seat belt tensioner

Explore More →Company Profile

Changzhou New WinPower Precision Technology Co.,Ltd.

Changzhou Xingweibang Precision Technology Co., Ltd. is located in the Yangtze River Delta with developed economy and strong growth momentum. It is equipped with convenient transportation services such as subway and customs. The company was established in 2012 with a total investment of more than 9000 million. Is a professional manufacturer of precision parts, according to customer needs, stainless steel, titanium alloy, high-temperature nickel-based alloy, Kovar alloy, carbon steel, aluminum alloy, copper alloy and other materials, customized processing. Products cover the automotive, rail, equipment, wind energy and other industries, to meet the high-precision, multi-batch precision machining requirements.

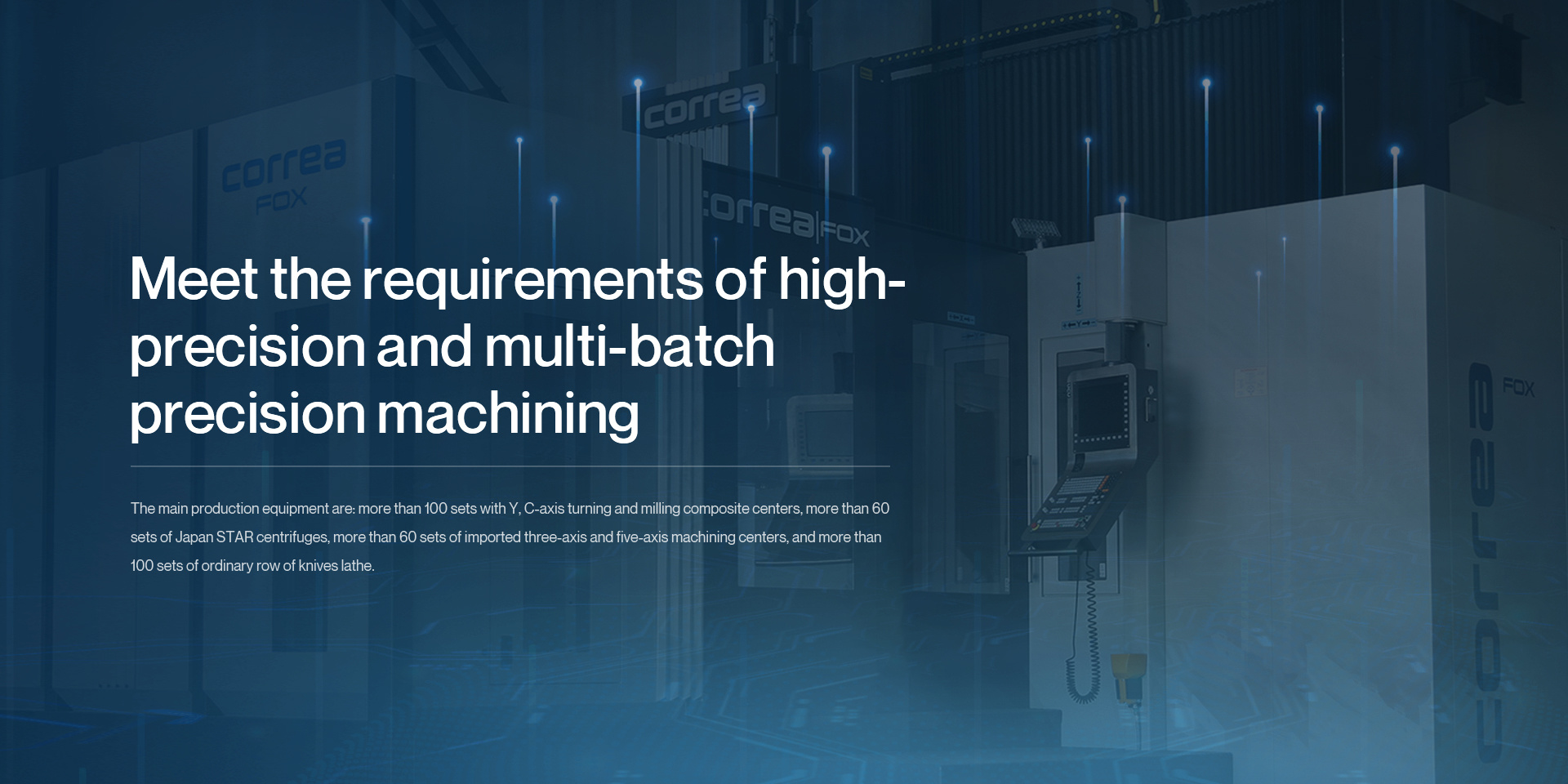

The main production equipment includes: more than 100 turning and milling compound centers with Y and C axes; More than 60 Japanese STAR walking machines; More than 60 imported three-axis and five-axis machining centers; DMG, Heck, Haas, Hiting, Brothers, etc. There are also more than 100 ordinary cutter lathes. Suitable for precision machining of large quantities of copper and aluminum materials; Two five-axis gantry Nicholas machining centers and one vertical turning and milling center; and equipped with cylindrical grinding, honing machine and other imported equipment.

Company industry experience

Main production equipment

Main testing instruments

Corporate Advantage

Quality service to customers in various industries

A professional manufacturer of precision parts can customize stainless steel, titanium alloy, high-temperature nickel-based alloy, Kovar alloy, carbon steel, aluminum alloy, copper alloy and other materials according to customer needs. Products cover the automotive, rail, equipment, wind energy and other industries, to meet the high-precision, multi-batch precision machining requirements.

01

Authoritative system certification

Products have passed ISO9001 and IATF16949 certification. Actively advocate green, low-carbon, energy-saving and environmentally friendly production methods and provide efficient logistics services.

02

Special processes and R & D products

According to customer needs, the production of finished and semi-finished raw materials such as stainless steel, titanium alloy, Kovar alloy, aluminum-magnesium alloy, copper alloy and various carbon steel can be completed.

03

advanced equipment

The company has successively introduced CORREA Fox five-axis linkage machining center, Japan Starstar slitting, Hurco, DMG, Haas machining center, and imported testing equipment.

04

product serialization

Products cover traditional cars and new energy vehicles, wind energy, rail transit, fluid pressure, communications, etc.

News Show

Always pay attention to Xingweigang information

Low carbon is another goal of the Chinese machinery industry during the "13th Five-Year Plan" period.

Wang Ruixiang, president of the China Machinery Industry Federation, pointed out that since the "Twelfth Five-Year Plan," as the machinery industry has bid farewell to high-speed growth and entered a period of adjustment and transformation, the deep-seated contradictions accumulated over the long term in the industry have become more prominent. To achieve the industry's "dual high" (high quality and high efficiency), it is necessary to break through four constraints that hinder the development of the machinery industry: weak innovation capability, imbalanced industrial structure, insufficient integrated development, and high energy consumption and pollution. The lack of strong independent innovation capability has always been a prominent issue restricting the development of the machinery industry. Wang Ruixiang introduced that the "Development Outline" proposes that during the "Thirteenth Five-Year Plan" period, the internal expenditure on R&D funds of enterprises above designated size should account for a certain proportion of their main business income.

17

2025-01

Wang Ruixiang, president of the China Machinery Industry Federation, pointed out that since the "Twelfth Five-Year Plan," as the machinery industry has bid farewell to high-speed growth and entered a period of adjustment and transformation, the deep-seated contradictions accumulated over the long term in the industry have become more prominent. To achieve the industry's "dual high" (high quality and high efficiency), it is necessary to break through four constraints that hinder the development of the machinery industry: weak innovation capability, imbalanced industrial structure, insufficient integrated development, and high energy consumption and pollution. The lack of strong independent innovation capability has always been a prominent issue restricting the development of the machinery industry. Wang Ruixiang introduced that the "Development Outline" proposes that during the "Thirteenth Five-Year Plan" period, the internal expenditure on R&D funds of enterprises above designated size should account for a certain proportion of their main business income.

17

2025-01

Analysis of Polishing Process Applications in Precision Machining

0 Introduction With the development of industry, the precision and complexity of machining are continuously improving. Especially with the advent of microcomputers, they have been widely applied in the field of industrial control, greatly enhancing processing efficiency. This allows machining to operate automatically and possess a certain level of intelligence. When problems arise, built-in expert systems can help resolve some issues. These technological advancements aim to improve the precision and efficiency of machining. The development of machining shows that the greatest difference in mechanical products from different periods lies in the precision of processing. For example, in today's daily life...

26

2024-12

Application of Five-axis Milling-Turning Hybrid Processing Technology in Advanced Equipment

In today’s era of global competition, the competition to reduce costs and increase added value is becoming increasingly fierce.

26

2017-12

China has become the main export market for U.S. components.

Hangya Technology held its 2017 semi-annual work meeting.

Provide precision machining solutions for various fields of hydraulic, automotive and industrial industries

Precision machining solutions for all areas of the hydraulic, automotive, and industrial industries

Contact Information

Telephone: 0086-519-8558090

Mobile: +86-13585302155 / +86-15895089837

E-mail: sales06@czxwb.com

Address: No.80, Wujin West Avenue, Wujin National High-tech Industrial Development Zone, Changzhou City, Jiangsu Province

Quick Navigation

Leave us a message

If you have any questions, please leave us a message or contact information, and we will contact you immediately.

Focus on us

Copyright©2025 Changzhou Xingwei Bang Precision Technology Co., Ltd. www.300.cn | SEO